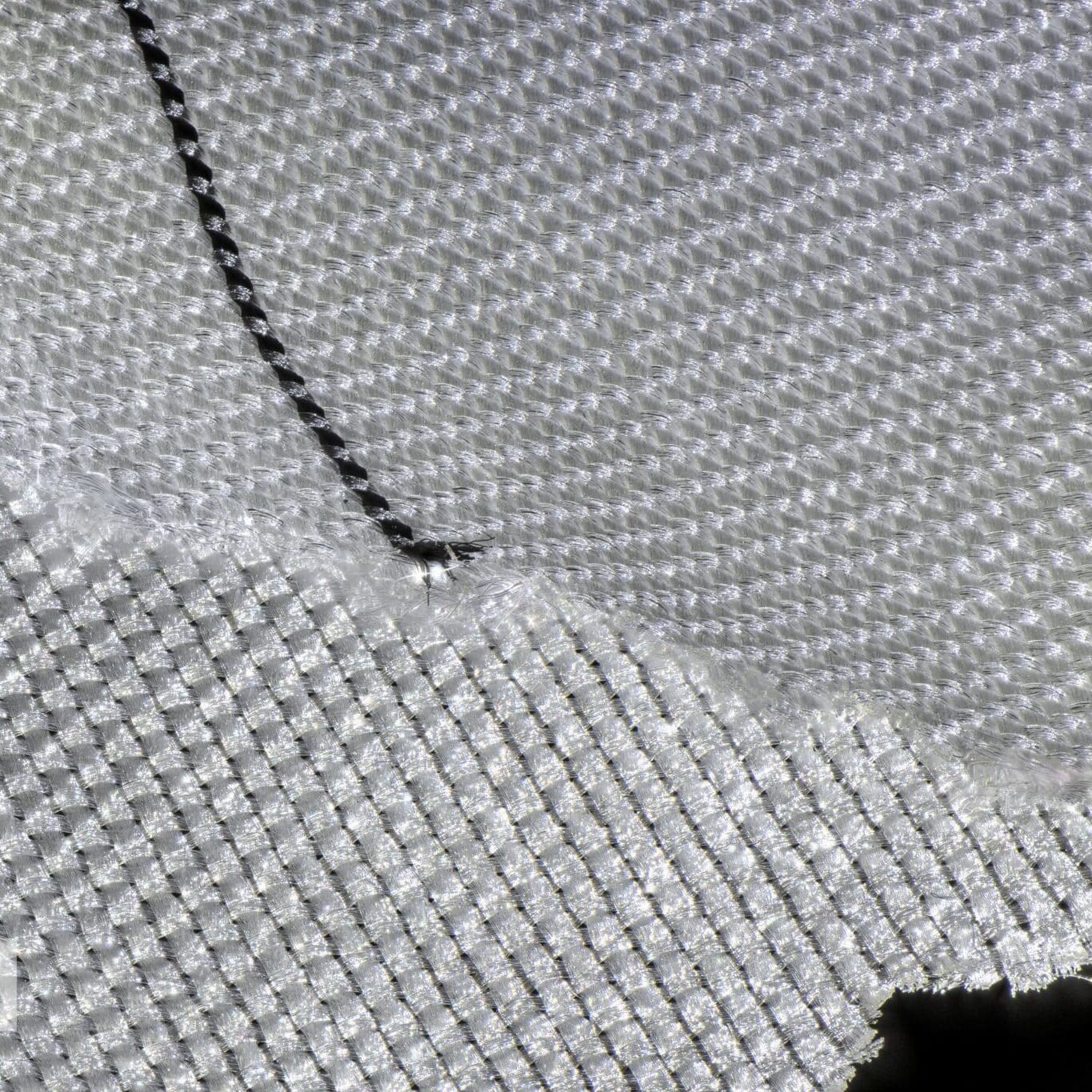

Tubular Fabrics

Click on the arrows to sort each parameter.

| Pattern Name | Weight oz/sq yard | Thickness (in) | Warp Tensile Strength (lbs) | Filling Tensile Strength (lbs) | Warp Thread Count (per in.) | Filling Thread Count (per in.) | Weave |

|---|---|---|---|---|---|---|---|

| A5921 | wing-tab |

EXPERIENCE AND KNOWLEDGE YOU CAN TRUST

Support

As a primary source provider for many of our clients, STERN EWS supports them by meeting expectations with consistency.